Directional Drilling

Trajectory Control

Directional drilling is the science of deviating a wellbore along a planned path, to a target located a given lateral distance and direction from vertical. This includes drilling as vertically as possible to a given true vertical depth (TVD).

NOVA Directional offers expert directional drillers, and proven technologies to provide the trajectory control needed to correctly drill your well. We ensure precise well placement, and a high-quality wellbore allowing for a successful run and cement casing, optimized production, and maximize recovery. NOVA Directional LWD and NOVA Directional MWD Services deliver high-quality data to enable time-critical decisions for accurate drilling of horizontal, vertical, extended-reach, and complex directional wells, as well as any necessary sidetracks.

Since 2011, NOVA Directional, Inc. has been a driving force in the horizontal/directional drilling industry. The managing partners and operations managers have more than 100 combined years of oilfield drilling experience so your next well is drilled accurately, safely, and on time. With some of the industry’s leading horizontal/directional drillers and support staff, NOVA is a well-defined leader in the field of horizontal/directional drilling. Simply stated, our goal is to accurately drill your well as quickly as possible with an emphasis on safety. Directional drilling involves a complex process of drilling non-vertical wells to increase energy production, decrease hazardous situations, and reduce environmental impacts. We design all of our projects to successfully recover hydrocarbons by using precise directional drilling equipment, accurate guidance solutions, and pinpoint monitoring software, along with the technical support to back it all up.

NOVA electromagnetic (EM) and Pressure Pulse (MP) Telemetry Measurement/Logging While Drilling (M/LWD) systems. Each MWD system is fully retrievable, and can be configured with Radial Gamma Ray. Our EM MWD also offers Focused Gamma Ray and Pressure While Drilling (PWD).

Directional Drilling:

NOVA Directional places wells precisely in the reservoir, evaluating the formation adjacent to the wellbore efficiently and accurately. We plan well trajectories while managing survey data combined with real-time reservoir navigation and visualization. We collaborate with you to maximize reservoir contact for increased production. Our directional drilling tool set includes the latest and best technology available today allowing us to complete your well project on schedule. The team of professional engineers, project managers and onsite staff stay in close contact with each other and the development company in order to provide safe and efficient well drilling services.

Horizontal Drilling:

Horizontal well drilling, which is a method of deviating the well until it is at, or close to a 90° angle from the vertical in order to drill out sideways and along a specific layer of rock. The trajectory of a well-bore starts vertically then steers horizontally at depth for thousands of feet. This allows increased contact between the well and the reservoir to increase productivity. Horizontal Drilling also provides access to reservoirs that are too thin to be fully accessed by vertical drilling.

Multilateral Drilling:

A single well-bore creates a trunk and then many branches stem from it, increasing production from a single drilling site. Multilateral drilling increases the contact area and allows for many branches to produce from the same well. These can be horizontal, curved slightly to one side, or turned sharply to form a J-type well. Multilateral drilling can occur in either new or existing oil and gas wells and typically includes two laterals. The main benefit of using this drilling approach is the increased efficiency and reduced cost of tapping multiple reservoir locations from a single point.

Extended Reach Drilling (ERD):

To figure out if the well is considered an ERW, calculate the ratio of horizontal departure to vertical depth. If the depth ratio is greater than 2, the well is considered an Extended Reach Well (ERW). An ERW can be relatively long and deep, short and shallow, or something in between. The benefit of Extended Reach Drilling is the increase in efficiency by exposing the open hole to long sections of the reservoir rock, or by crossing through multiple reservoirs in one long well-bore. It is expensive and risky but it is sometimes the best option available. With advances in technology, these wells are getting longer and longer as we get better at overcoming the challenges of managing down-hole pressure, managing and controlling the mechanical loads on the drill string, and hole cleaning.

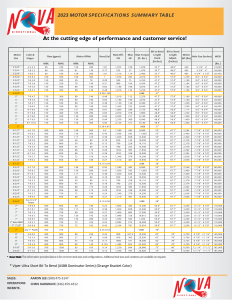

NOVA Directional provides a wide range of the most reliable drilling motors that today’s market demands.

All drilling motors are manufactured in the USA, produced from the best materials and strictest quality standards available in the industry.

Here is a list/specs of motor configurations available for the most common hole sizes.

NOVA Directional Inc. MWD System delivers enhanced performance, stability, and advanced features to horizontal and directional drilling operations worldwide. Our down-hole tools include electronics, directional sensors, gamma probes, pulsers, and battery packs that are configurable and customizable to meet your specific MWD needs.

The probe can be deployed in standard non-magnetic drill collars and is fully retrievable and reinsert-able. Bench Tree’s Surface Systems include an industry-leading data acquisition, decoding, and display technologies: advanced receivers, rugged displays, transducers, wireless systems, feature-rich software, and web-based services.

Retrievable and Reseatable

High-operating temperature: 175°C (347°F)

Handles LCM better than most

Advertise a 1,800 hr MTBF on directional sensors

RINC – Real-time inclination while rotating or sliding

Real-time Shock and Vibration monitoring

Dynamic Sequencing – Allows for transmission of different logging sequences based on tool rotation.

Dynamic survey – On demand survey triggered by rotating without having to cycle the pumps.

Experience Counts

|

NOVA Directional has created various partnerships

|

|---|

Service Areas

- Colorado/Wyoming

- Pieance

- Niobrara

- North Dakota

- Bakken Shale

- Three Forks

- Spearfish/Charles/Midale

- Kansas:

- Mississippian Lime

- Louisiana:

-

- Haynesville Shale

- Various South LA sands

-

- Texas:

- Permian Basin

- Eagleford Shale

- Austin Chalk

- Buda/Georgetown

- Barnett Shale

- South Texas Frio

- Wilcox

-

- Oklahoma:

- STACK

- SCOOP

- Woodford Shale

- Cleveland/Tonkawa

- Mississippian

- Granite Wash

- Oklahoma: